Sonatrach, Algeria’s state-owned oil and gas leader, is making strides in the renewable energy sector through a promising discussion with Coolergy S.L., a Spanish engineering company specializing in liquid hydrogen solutions. The meeting, involving Sonatrach’s director for green and renewable energy, Youcef Khanafar, and Coolergy’s CEO, Kirill Lyats, was held at Sonatrach’s headquarters in Algiers.

Sonatrach, Algeria’s state-owned oil and gas leader, is making strides in the renewable energy sector through a promising discussion with Coolergy S.L., a Spanish engineering company specializing in liquid hydrogen solutions. The meeting, involving Sonatrach’s director for green and renewable energy, Youcef Khanafar, and Coolergy’s CEO, Kirill Lyats, was held at Sonatrach’s headquarters in Algiers.

Strong Hints of a Bose Metal

![A strong enough magnetic field destroys superconductivity even at absolute zero. But in some materials, known as type-II superconductors, superconductivity and magnetic-field-induced vortices can coexist before that threshold is crossed. Type-II superconductivity becomes more fragile as the superconductor becomes thinner. Eventually, some theorists say, the combination of an applied magnetic field and two dimensionality begets a Bose metal, a finite-resistance state whose charge carriers, like those in a superconductor, are Cooper-paired electrons. Now Xiaoxiang Xi of Nanjing University, China, and his collaborators have found evidence consistent with a Bose metal in atomically thin films of niobium diselenide (NbSe2) [1]. A strong enough magnetic field destroys superconductivity even at absolute zero. But in some materials, known as type-II superconductors, superconductivity and magnetic-field-induced vortices can coexist before that threshold is crossed. Type-II superconductivity becomes more fragile as the superconductor becomes thinner. Eventually, some theorists say, the combination of an applied magnetic field and two dimensionality begets a Bose metal, a finite-resistance state whose charge carriers, like those in a superconductor, are Cooper-paired electrons. Now Xiaoxiang Xi of Nanjing University, China, and his collaborators have found evidence consistent with a Bose metal in atomically thin films of niobium diselenide (NbSe2) [1].](https://cryo.memberclicks.net/assets/news/bose%20metal.png) A strong enough magnetic field destroys superconductivity even at absolute zero. But in some materials, known as type-II superconductors, superconductivity and magnetic-field-induced vortices can coexist before that threshold is crossed. Type-II superconductivity becomes more fragile as the superconductor becomes thinner. Eventually, some theorists say, the combination of an applied magnetic field and two dimensionality begets a Bose metal, a finite-resistance state whose charge carriers, like those in a superconductor, are Cooper-paired electrons. Now Xiaoxiang Xi of Nanjing University, China, and his collaborators have found evidence consistent with a Bose metal in atomically thin films of niobium diselenide (NbSe2) [1].

A strong enough magnetic field destroys superconductivity even at absolute zero. But in some materials, known as type-II superconductors, superconductivity and magnetic-field-induced vortices can coexist before that threshold is crossed. Type-II superconductivity becomes more fragile as the superconductor becomes thinner. Eventually, some theorists say, the combination of an applied magnetic field and two dimensionality begets a Bose metal, a finite-resistance state whose charge carriers, like those in a superconductor, are Cooper-paired electrons. Now Xiaoxiang Xi of Nanjing University, China, and his collaborators have found evidence consistent with a Bose metal in atomically thin films of niobium diselenide (NbSe2) [1].

Read More

Accidental Breakthrough As Supercooled Wires Detect Near-Light-Speed Protons

Particle detectors are essential tools for studying the fundamental components of the universe. They help scientists analyze the behavior and properties of particles created in high-energy collisions. In these experiments, particles are accelerated to nearly the speed of light and then smashed into targets or other particles. Detectors capture and measure the results, revealing valuable insights. However, traditional detectors often lack the sensitivity and precision needed for certain types of research.

Particle detectors are essential tools for studying the fundamental components of the universe. They help scientists analyze the behavior and properties of particles created in high-energy collisions. In these experiments, particles are accelerated to nearly the speed of light and then smashed into targets or other particles. Detectors capture and measure the results, revealing valuable insights. However, traditional detectors often lack the sensitivity and precision needed for certain types of research.

Read More

Researchers using NASA’s James Webb Space Telescope have finally solved the mystery of how a massive galaxy cluster is forming stars at such a high rate. The confirmation from Webb builds on more than a decade of studies using NASA’s Chandra X-ray Observatory and Hubble Space Telescope, as well as several ground-based observatories.

Researchers using NASA’s James Webb Space Telescope have finally solved the mystery of how a massive galaxy cluster is forming stars at such a high rate. The confirmation from Webb builds on more than a decade of studies using NASA’s Chandra X-ray Observatory and Hubble Space Telescope, as well as several ground-based observatories.

Read More

In a development that validates large-scale liquid hydrogen tank technology for shipping, HD Korea Shipbuilding & Offshore Engineering (HD KSOE) has received approval in principle (AIP) from ABS for a tank design that enables large-scale hydrogen transportation and storage. ABS completed design reviews based on class and statutory requirements.

In a development that validates large-scale liquid hydrogen tank technology for shipping, HD Korea Shipbuilding & Offshore Engineering (HD KSOE) has received approval in principle (AIP) from ABS for a tank design that enables large-scale hydrogen transportation and storage. ABS completed design reviews based on class and statutory requirements.

Read More

NASA crew aboard the International Space Station installed patches to the agency’s NICER (Neutron star Interior Composition Explorer) mission during a spacewalk on Jan. 16. NICER, an X-ray telescope perched near the station’s starboard solar array, resumed science operations later the same day.

NASA crew aboard the International Space Station installed patches to the agency’s NICER (Neutron star Interior Composition Explorer) mission during a spacewalk on Jan. 16. NICER, an X-ray telescope perched near the station’s starboard solar array, resumed science operations later the same day.

Read More

In late July 2024, the Malargüe deep-space communication station completed a significant upgrade to its antenna feed, increasing its data transmission capacity by almost 80%.

In late July 2024, the Malargüe deep-space communication station completed a significant upgrade to its antenna feed, increasing its data transmission capacity by almost 80%.Read More

Dover announced that it has acquired Cryogenic Machinery Corp. ("Cryo-Mach"). The acquisition will become part of the PSG business within Dover's Pumps & Process Solutions segment, expanding Dover's presence in the cryogenic end market.

Dover announced that it has acquired Cryogenic Machinery Corp. ("Cryo-Mach"). The acquisition will become part of the PSG business within Dover's Pumps & Process Solutions segment, expanding Dover's presence in the cryogenic end market.

Read More

Temperature-controlled supply chain solutions specialist Cryoport has launched a new high-volume cryogenic shipping system. The Express® Cryogenic shipping system, HV3 for short, is designed to meet the needs of advanced therapies, keeping temperature stable at -150°C and is compliant with airline requirements to allow for air travel.

Temperature-controlled supply chain solutions specialist Cryoport has launched a new high-volume cryogenic shipping system. The Express® Cryogenic shipping system, HV3 for short, is designed to meet the needs of advanced therapies, keeping temperature stable at -150°C and is compliant with airline requirements to allow for air travel.

Read More

In 2024, superconductivity—the flow of electric current with zero resistance—was discovered in three distinct materials. Two instances stretched the textbook understanding of the phenomenon, while the third defied it entirely. “It’s an extremely unusual form of superconductivity that a lot of people would have said is not possible,” said Ashvin Vishwanath, a physicist at Harvard University who was not involved in the discoveries.

In 2024, superconductivity—the flow of electric current with zero resistance—was discovered in three distinct materials. Two instances stretched the textbook understanding of the phenomenon, while the third defied it entirely. “It’s an extremely unusual form of superconductivity that a lot of people would have said is not possible,” said Ashvin Vishwanath, a physicist at Harvard University who was not involved in the discoveries.

Read More

Over 150 research and industry experts gathered in London for a Cryogenic Hydrogen Research Conference delivered by the ATI’s Hydrogen Capability Network (HCN) in partnership with the Civil Aviation Authority this week. This inaugural HCN conference with a cryogenics focus brought together academics, students, and industry engineers working in the field of cryogenic hydrogen to share knowledge and foster a collaborative community.

Over 150 research and industry experts gathered in London for a Cryogenic Hydrogen Research Conference delivered by the ATI’s Hydrogen Capability Network (HCN) in partnership with the Civil Aviation Authority this week. This inaugural HCN conference with a cryogenics focus brought together academics, students, and industry engineers working in the field of cryogenic hydrogen to share knowledge and foster a collaborative community.

Read More

Entering its 65th year of operation, Demaco Holland B.V., based in Noord-Scharwoude, The Netherlands, proudly announces the release of its new logo and brand identity. The refreshed branding signifies Demaco’s integration as a core member of OPW Clean Energy Solutions, a business unit of OPW, a Dover company, following its acquisition in the summer of 2024.

Entering its 65th year of operation, Demaco Holland B.V., based in Noord-Scharwoude, The Netherlands, proudly announces the release of its new logo and brand identity. The refreshed branding signifies Demaco’s integration as a core member of OPW Clean Energy Solutions, a business unit of OPW, a Dover company, following its acquisition in the summer of 2024.

Read More

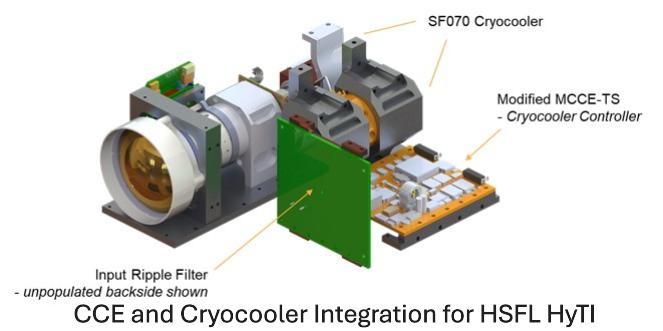

West Coast Solutions (WCS) has experienced remarkable growth since its founding in 2015 by Dr. Carl Kirkconnell. From its origins as a one-person operation, the company has expanded to a team of over 40, 80% of whom are engineers. Anchored by a core group of seasoned professionals—many former Raytheon colleagues—and bolstered by a dynamic team of early-career engineers, WCS has cultivated a unique balance of experience and innovation. Cryogenics remains a central focus, reflecting Dr. Kirkconnell’s expertise in the field. This foundation, combined with technical adjacencies, has enabled WCS to establish three thriving business sectors: cryogenics, aerospace and electronics and power.

West Coast Solutions (WCS) has experienced remarkable growth since its founding in 2015 by Dr. Carl Kirkconnell. From its origins as a one-person operation, the company has expanded to a team of over 40, 80% of whom are engineers. Anchored by a core group of seasoned professionals—many former Raytheon colleagues—and bolstered by a dynamic team of early-career engineers, WCS has cultivated a unique balance of experience and innovation. Cryogenics remains a central focus, reflecting Dr. Kirkconnell’s expertise in the field. This foundation, combined with technical adjacencies, has enabled WCS to establish three thriving business sectors: cryogenics, aerospace and electronics and power.

Read More

![]() Volcanism is one of Earth’s most powerful forces, reshaping landscapes and impacting ecosystems in dramatic ways. To advance the prediction of volcanic eruptions, INFICON GmbH, a leader in measurement and sensor technologies, is partnering with scientists and research institutions to monitor volcanic activity on Italy’s Vulcano and Stromboli islands. This collaboration uses INFICON’s advanced instruments to perform geochemical measurements of gases emitted from the ground, offering insights that could help forecast eruptions with greater accuracy.

Volcanism is one of Earth’s most powerful forces, reshaping landscapes and impacting ecosystems in dramatic ways. To advance the prediction of volcanic eruptions, INFICON GmbH, a leader in measurement and sensor technologies, is partnering with scientists and research institutions to monitor volcanic activity on Italy’s Vulcano and Stromboli islands. This collaboration uses INFICON’s advanced instruments to perform geochemical measurements of gases emitted from the ground, offering insights that could help forecast eruptions with greater accuracy.

Read More

By streamlining the acquisition, recertification and repair of gas cylinders, industrial gas distributors can increase profitability. Industrial gas distributors, responsible for filling and supplying compressed gas cylinders for sale or rental, are crucial to diverse sectors. They deliver essential gases like nitrogen, oxygen, argon, carbon dioxide, hydrogen, helium, methane and propane to a variety of industries, including electronics, government, medical, welding, food and beverage, fire protection and aviation.

By streamlining the acquisition, recertification and repair of gas cylinders, industrial gas distributors can increase profitability. Industrial gas distributors, responsible for filling and supplying compressed gas cylinders for sale or rental, are crucial to diverse sectors. They deliver essential gases like nitrogen, oxygen, argon, carbon dioxide, hydrogen, helium, methane and propane to a variety of industries, including electronics, government, medical, welding, food and beverage, fire protection and aviation.

Read More

Stirling Cryogenics’ World Tour

Given the theme of this issue of Cold Facts, Stirling Cryogenics would like to take you on a tour of our 70-year history, telling about our recent and vintage cryogenerators and systems all around the world. Universities worldwide have been our customers from the very beginning, cheering in the 1950s that they could now produce their own LN2. In South America, proud examples include systems at the Universidad de Chile since 1964 and IVIC in Venezuela where the old Philips Cryogenerator was replaced with a new system after 45 years of operation. The University of Buenos Aires in Argentina has several systems in operation of which the oldest cryogenerator was installed in 1958 providing 66 years of service!

Given the theme of this issue of Cold Facts, Stirling Cryogenics would like to take you on a tour of our 70-year history, telling about our recent and vintage cryogenerators and systems all around the world. Universities worldwide have been our customers from the very beginning, cheering in the 1950s that they could now produce their own LN2. In South America, proud examples include systems at the Universidad de Chile since 1964 and IVIC in Venezuela where the old Philips Cryogenerator was replaced with a new system after 45 years of operation. The University of Buenos Aires in Argentina has several systems in operation of which the oldest cryogenerator was installed in 1958 providing 66 years of service!

Read More

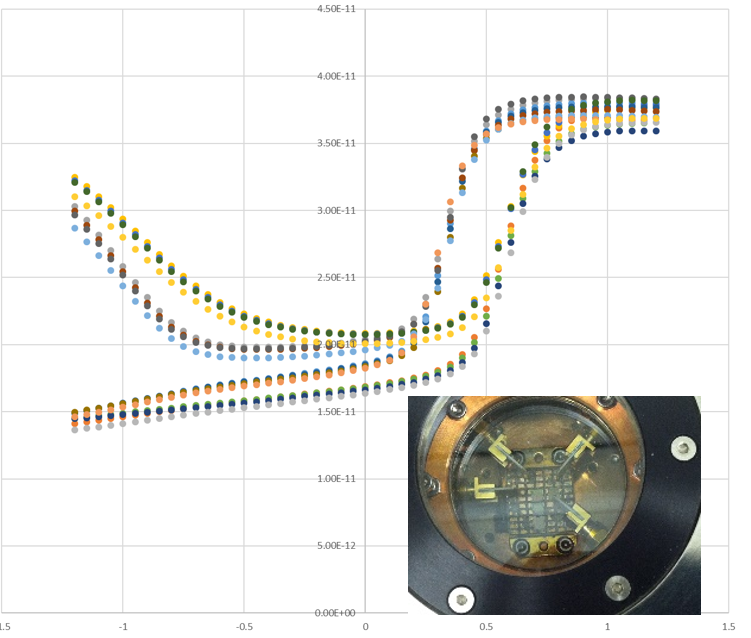

CoolCAD Electronics is a leading provider of electrical test services (current-voltage, capacitance-voltage, noise, transients, etc.) and compact modeling (SPICE) for companies and agencies fabricating and/or designing electronics for low temperature operation. CoolCAD Electronics is a leading-edge company specializing in cryogenic electronics design, testing, and characterization of semiconductor devices operating at ultralow temperatures. With the growing importance of cryogenic technologies in fields like quantum computing, superconducting circuits, and high-performance computing, CoolCAD addresses the unique challenges posed by extreme environments. The company’s work enables precise device characterization at temperatures as low as 4 K, offering insights into semiconductor behavior and performance in cryogenic conditions. As demand for robust, high-performance cryogenic electronics increases, CoolCAD provides the tools and expertise required to ensure reliability and functionality in these challenging environments.

CoolCAD Electronics is a leading provider of electrical test services (current-voltage, capacitance-voltage, noise, transients, etc.) and compact modeling (SPICE) for companies and agencies fabricating and/or designing electronics for low temperature operation. CoolCAD Electronics is a leading-edge company specializing in cryogenic electronics design, testing, and characterization of semiconductor devices operating at ultralow temperatures. With the growing importance of cryogenic technologies in fields like quantum computing, superconducting circuits, and high-performance computing, CoolCAD addresses the unique challenges posed by extreme environments. The company’s work enables precise device characterization at temperatures as low as 4 K, offering insights into semiconductor behavior and performance in cryogenic conditions. As demand for robust, high-performance cryogenic electronics increases, CoolCAD provides the tools and expertise required to ensure reliability and functionality in these challenging environments.

Read More

Meet Our New Board Members

As the Cryogenic Society of America moves into an exciting era of innovation and exploration, we’re thrilled to introduce the talented professionals who will help guide our organization forward. This year’s new board members bring a wealth of expertise from diverse sectors within the field, as well as a shared passion for advancing cryogenic science and technology. Join us as we highlight their unique journeys, perspectives, and vision for the future of cryogenics—a future they’re already shaping through their leadership and commitment.

Read More

Astoriom, a global leader in life sciences R&D sample stability and biorepository storage, has unveiled a cutting-edge cryogenic storage suite at its Tramore facility in County Waterford. This new development brings unparalleled capabilities for biological sample storage to Ireland.

Astoriom, a global leader in life sciences R&D sample stability and biorepository storage, has unveiled a cutting-edge cryogenic storage suite at its Tramore facility in County Waterford. This new development brings unparalleled capabilities for biological sample storage to Ireland.

Read More

Thermal management solutions provider Advanced Cooling Technologies has received a $1 million order from Hamilton Storage to support its biological sample storage freezers. The order includes cryogenic cold walls integral to Hamilton Storage’s ongoing cold plate programme, which ensures consistent temperatures for sensitive biological specimens.

Thermal management solutions provider Advanced Cooling Technologies has received a $1 million order from Hamilton Storage to support its biological sample storage freezers. The order includes cryogenic cold walls integral to Hamilton Storage’s ongoing cold plate programme, which ensures consistent temperatures for sensitive biological specimens.