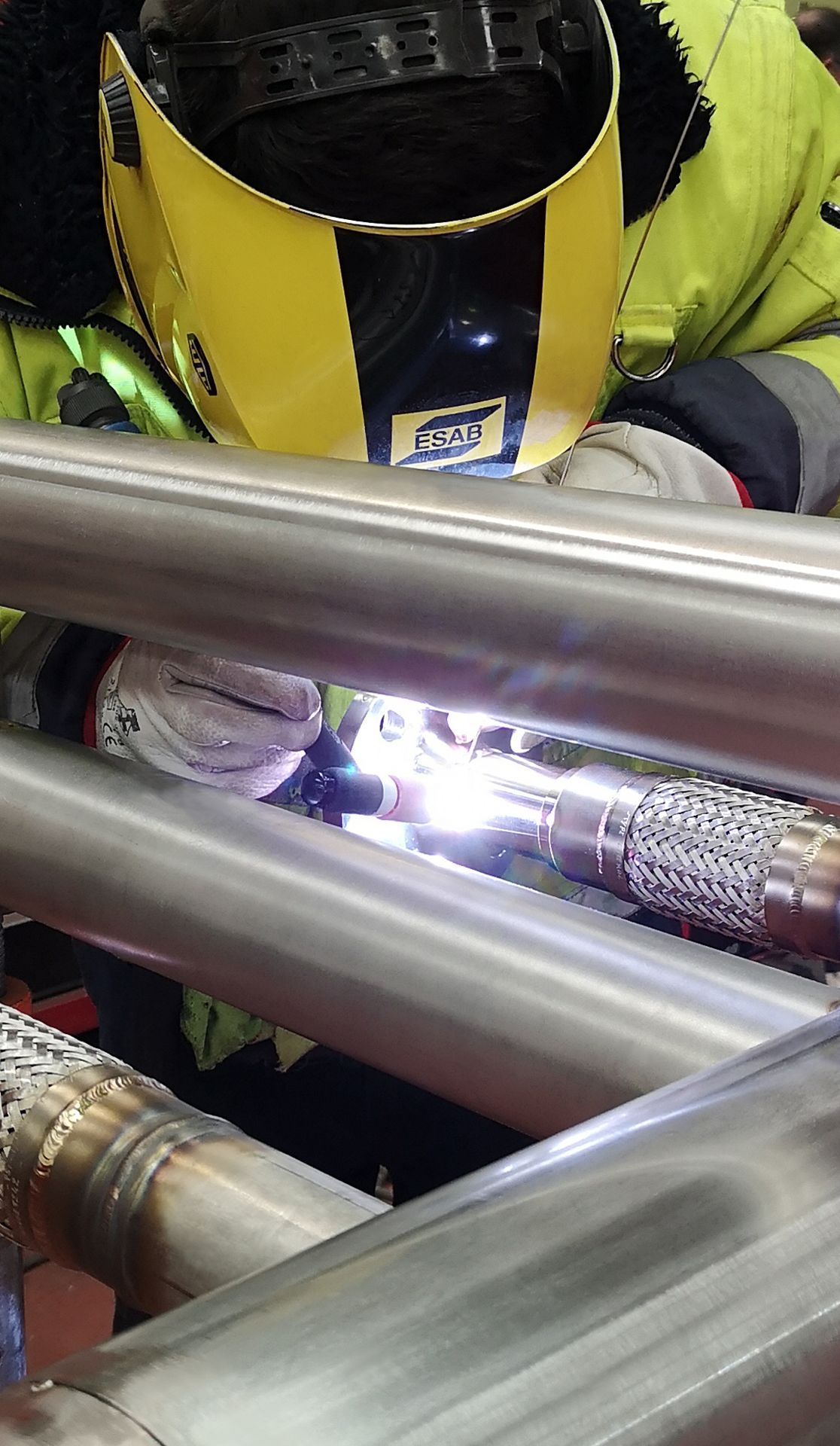

Cryospain demonstrates its dedication to pioneering cryogenic equipment through the design and production of state-of-the-art super-insulated pipes for cryogenics employing high vacuum technology. Positioned at the forefront of progress toward a more sustainable future, Cryospain continues to assert its central role in advancing innovative solutions.

Cryospain demonstrates its dedication to pioneering cryogenic equipment through the design and production of state-of-the-art super-insulated pipes for cryogenics employing high vacuum technology. Positioned at the forefront of progress toward a more sustainable future, Cryospain continues to assert its central role in advancing innovative solutions.

The latest endeavor in Rotterdam exemplifies Cryospain's commitment, where the company has been instrumental in the conception, acquisition, fabrication, and provision of vacuum-insulated piping systems. These systems are essential for the safe and efficient transportation, distribution, and filling of tank trucks destined to carry liquid hydrogen to end consumers.

Liquid hydrogen emerges as a promising clean energy source in the journey towards decarbonization and energy transition. Effectively storing and transporting hydrogen in its liquid state is paramount for progress in this direction, granting a competitive edge to companies capable of doing so efficiently and securely.

Cryospain emerges as a key player in facilitating the safe handling of liquid hydrogen, providing cutting-edge technology and specialized equipment. Their involvement in the Rotterdam project underscores their pivotal role in advancing the utilization of liquid hydrogen.

Collaborating with a leading gas company boasting over 80 years of experience in liquefied air gases distribution and cryogenic operations, Cryospain aligns itself with the growing importance of liquid hydrogen. The company's partnership in constructing a second liquid hydrogen liquefaction plant, slated for completion by 2025, aims to double Europe's liquid hydrogen supply capacity.

This expanded supply will cater to various high-tech industries, including aerospace, automotive, and sustainable energy sectors, positioning projects like the Rotterdam endeavor as pioneers in sustainable mobility and clean energy generation.

Cryospain's contributions to the project encompass the comprehensive lifecycle of the vacuum insulated piping system. From initial design and procurement to manufacturing and supply, Cryospain's involvement ensures meticulous attention to detail and adherence to stringent quality standards.

The project timeline delineates Cryospain's phased approach, commencing with the design phase in July 2023 and culminating in the integration and delivery stages through mid-2024. The supplied pipes, ranging from vacuum-insulated to single and double-wall configurations, undergo rigorous testing to ensure compliance with regulatory standards and optimal thermal performance.

Technical specifications underscore Cryospain's commitment to excellence, with meticulous attention to detail in meeting regulatory directives and industry standards. Quality assurance measures include thermal performance tests, helium leak tests, and pressure tests, ensuring the utmost reliability and safety of the supplied piping systems.

In summary, Cryospain's participation in the Rotterdam project exemplifies its dedication to providing tailored solutions that meet the evolving needs of its clients. By leveraging its expertise in cryogenic technology, Cryospain plays a pivotal role in advancing sustainable practices and contributing to a greener future.

Image: Cryospain designs and produces super-insulated pipes for cryogenics using high vacuum. Credit: Cryospain