RIX Liquid Oxygen Generation Plant Supports US Navy’s Newest Aircraft Carriers

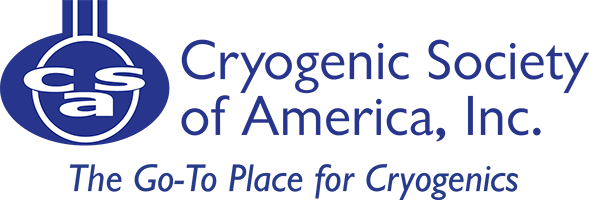

Aircraft carriers use highly concentrated gaseous and liquid oxygen for aviation and medical applications. These legacy systems consume large amounts of valuable ship space and require constant attention and adjustment to meet purity and production rates. With the development of USS Gerald R. Ford (CVN-78) – the “first-in-class” nuclear-powered aircraft carrier designed to replace the aging Nimitz-class carriers in service for over 50 years – the Navy and its contracted partners determined an opportunity for improvement. By implementing a modern liquid oxygen plant in the new Ford-class fleet design, the Navy could achieve its key goals of reducing cost of ownership, decreasing operational manpower, and significantly reducing overall maintenance demands.

Aircraft carriers use highly concentrated gaseous and liquid oxygen for aviation and medical applications. These legacy systems consume large amounts of valuable ship space and require constant attention and adjustment to meet purity and production rates. With the development of USS Gerald R. Ford (CVN-78) – the “first-in-class” nuclear-powered aircraft carrier designed to replace the aging Nimitz-class carriers in service for over 50 years – the Navy and its contracted partners determined an opportunity for improvement. By implementing a modern liquid oxygen plant in the new Ford-class fleet design, the Navy could achieve its key goals of reducing cost of ownership, decreasing operational manpower, and significantly reducing overall maintenance demands.

Early in the vessel’s development process, the Navy, in conjunction with Huntington Ingalls and Northrop Grumman, recognized that traditional liquid oxygen-generating systems were very difficult to operate, required routine maintenance, and consumed large amounts of energy. Many legacy production plants utilize fractional distillation column technology to produce high-purity oxygen and turbo Brayton cryogenic plants for liquefaction. In addition, each plant typically takes 20 or more hours to reach stability, an unacceptable amount of time for the Navy to reach operational readiness.

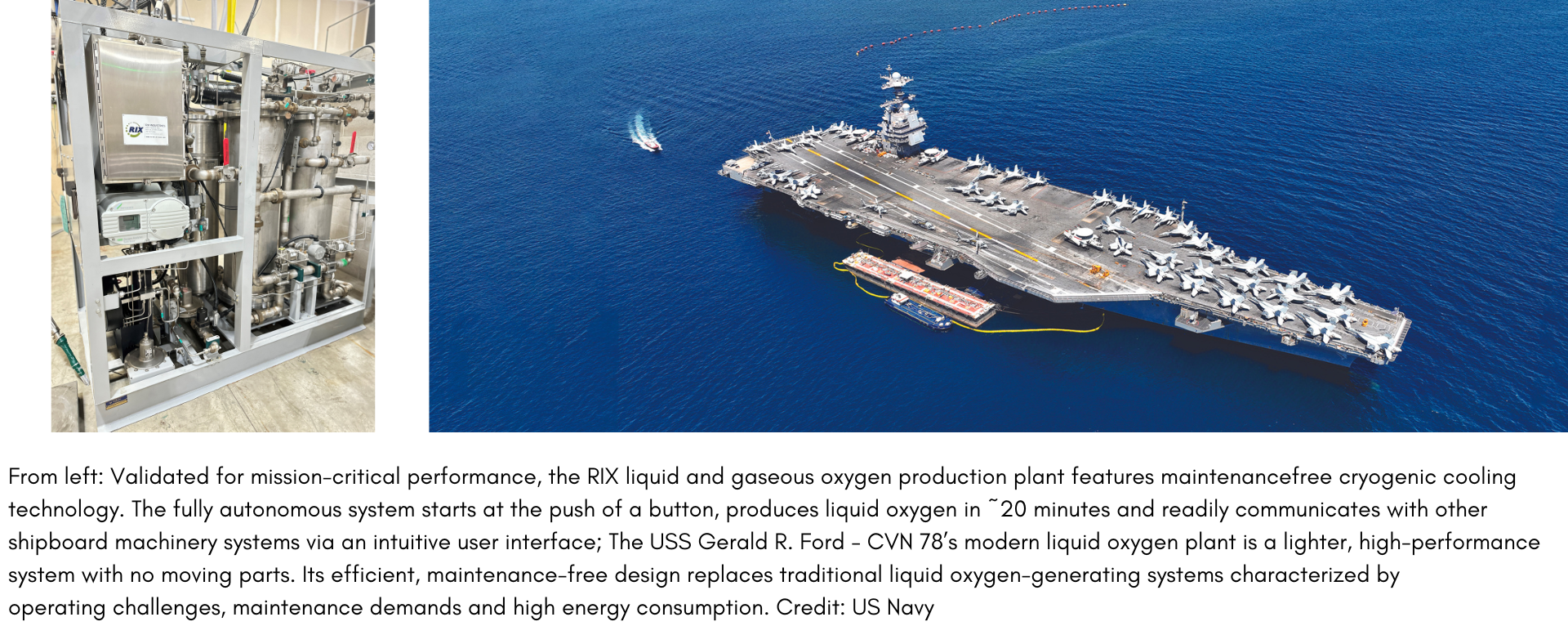

The RIX Solution: To meet the need for improvement, RIX Industries, in partnership with Chart Industries/Qdrive, developed a state-of-the-art Liquid Oxygen, or LOX, plant utilizing a large Thermoacoustic Stirling Cryocooler (TASC) and a militarized Vacuum Pressure Swing Adsorption (VPSA) oxygen generator. Together, these sophisticated technologies promise benefits in safety, performance, and reliability. The system operates at 50psi, liquefies oxygen at approximately 100 K, and operates autonomously to start liquefying LOX in under 20 minutes.

The TASC consists of three (3) coldheads that have absolutely no moving parts. The compressor, or Pressure Wave Generator (PWG), utilizes two 10kW linear reciprocating motors opposed to each other, cancelling vibration and reducing noise, another significant advantage for naval installations. The motors feature flexure bearings that do not require lubrication, and the pistons utilize non-contact clearance seals that eliminate wear, creating an efficient, maintenance-free design. In addition, the size/weight of the RIX cryocooler is approximately 50% the size of its predecessor and the TASC is impervious to ship movement.

“I’ve not experienced a better example of teamwork during the development of this system,” says Jerry Stultz, former director of DOD/Navy Programs and current Chief Operations Officer at RIX. “We dramatically reduced the size and weight of the plant while satisfying the ship’s production and crew member reduction requirements. It’s truly satisfying to participate in building an increasingly bright future for the US Navy’s aircraft carrier fleet.”

Rigorous Testing: All Navy-approved shipboard equipment must pass a series of rigorous tests that prove the equipment is suitable for extreme use in mission-critical scenarios. Testing criteria encompasses extensive shock, noise, and vibration tests, as well as power quality analysis to ensure signals generated by the equipment do not interfere with other critical shipboard systems. During a particular naval shock test, (MIL-S-901D) the complete RIX system was subjected to multiple shock episodes, with the highest test imparting an impressive 80-Gs of acceleration directly on the cryocooler. Although it was not required to operate after this test, the TASC not only survived with very little damage, but it was able to reach cryogenic temperatures in 10 minutes and LOX liquefaction temperatures in 20 minutes. The RIX system also passed the Navy’s extreme builders and acceptance trials performed at sea.

Conclusion: Historically, startup and operation of legacy liquid oxygen production plants deployed on Navy aircraft carriers and hospital ships required highly trained personnel. Today, RIX Industries provides a fully autonomous system that starts at the push of a button and produces liquid oxygen in 20 minutes. The RIX liquid and gaseous oxygen production plant also uses maintenance-free cryogenic cooling technology and provides an intuitive user interface that communicates with other shipboard machinery systems. The RIX LOX plant’s rugged, reliable design and extraordinary test results have validated its performance during mission-critical scenarios and in harsh environments. In fact, the USS Gerald R. Ford recently returned from an 8-month mission in the Mediterranean Sea after successfully conducting operations in the US Sixth Fleet. RIX is proud and honored to be part of that CVN-78 mission and future CVN missions. www.rixindustries.com

Lead Image: Navy testing criteria encompasses extensive shock, noise, and vibration tests, as well as power quality analysis. The RIX Industries’ LOX system is validated to MIL-S-901D and also passed the Navy’s extreme builders and acceptance trials performed at sea. Credit: RIX Industries