Bluefors Lab Offers Cryo Measurements, a Low Risk Model for Experiments

Quantum technology continues to develop at a rapid pace, and the need for access to cryogenic cooling systems for quantum research has never been greater. While established institutions have an increasing number of options to choose from, startups and smaller institutions still face considerable challenges, not least of which are the costs involved in investing in a dedicated cryogenic measurement system for their experiments.

Quantum technology continues to develop at a rapid pace, and the need for access to cryogenic cooling systems for quantum research has never been greater. While established institutions have an increasing number of options to choose from, startups and smaller institutions still face considerable challenges, not least of which are the costs involved in investing in a dedicated cryogenic measurement system for their experiments.

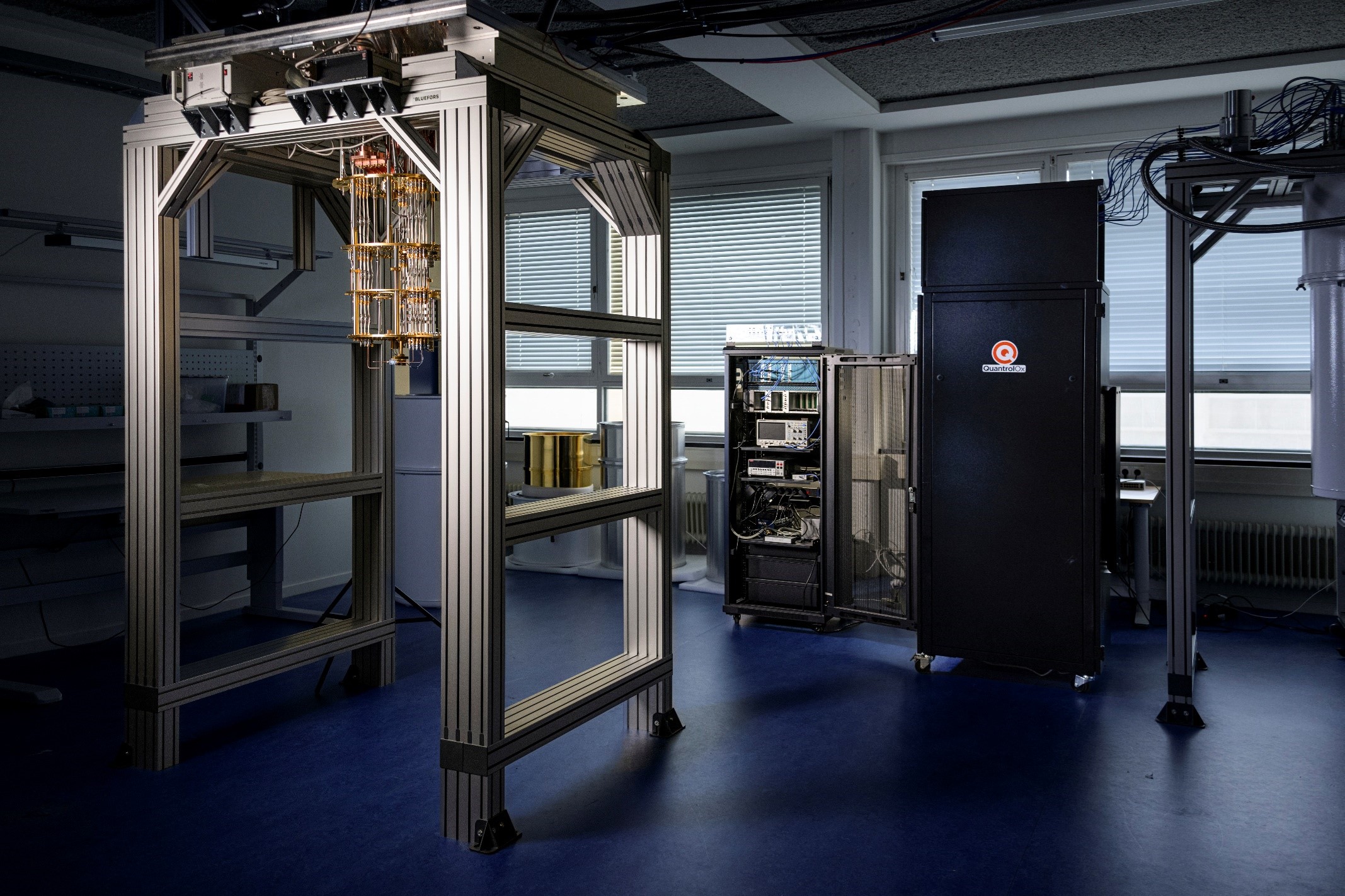

One solution that offers enormous flexibility and cost savings is cryogenic measurements as a service, such as the service offered at Bluefors Lab in Delft, Netherlands. Recognizing the need for smaller companies to get their foot in the door with industry-leading technology, the Bluefors Lab offers proven benchmark products that the cryogenic industry relies upon, and makes them accessible and affordable.

A Full Suite of Cryogenic Tools

Bluefors has a deep understanding of the cryogenic equipment needs of customers around the world. A dilution refrigerator is of very little practical use without the supporting electronics needed for qubit control and measurement. The key advantages of the service-model access to cryogenic measurement systems at Bluefors Lab is the provision of a full suite of electronics for the LD system, and the integration of specialized wiring developed in-house that optimizes performance.

The Lab in Delft offers both LD400 and XLD1000sl dilution refrigerators complete with RF coaxial and DC twisted pair wiring, with both systems designed to be used with common superconducting qubit chips.

The LD system setup supports up to 5 qubits and is ideal for shorter measurement periods, delivering 15 µW cooling power at 20 mK on an 11.42-inch (294mm) experimental flange. The XLDsl is ideal for more demanding experiments, with a large 20-inch (500mm) flange, pre-installed Microwave Readout Module with travelling wave parametric amplifier, and the possibility for custom setups that utilize its side-loading technology.

The Lab’s measurement electronics include everything needed for successful experiments. The LD service includes an OrangeQS rack, Qblox Cluster for RF control and readout, a Qblox SPI rack as a DC source, a spectrum analyzer, an oscilloscope and source measurement unit. There is also other commonly used equipment, such as a VNA, amplifiers, attenuators and test cables at the lab.

For many companies, this package not only offers a complete quantum computing setup, but it establishes baseline access to industry-standard tools. In this way, users are able to start off on the right foot and familiarize themselves with technology used worldwide.

Support That Drives Results

Another significant advantage to the cryogenic measurements as a service model is the support of the knowledgeable, experienced staff at the Lab. In Delft, the lab team is available on site to help customers through all phases, from operating and monitoring the cryostats, helping with sample installation, supporting the electronics setup and ensuring that users get the most value from their lab time.

Much of this supporting work comes down to extensive preparation and operational maintenance, so that when customers arrive everything is ready and in working order. Users do not need to visit the lab every day — the systems have been designed with remote operation in mind, so minor changes in measurement setup can be handled by the Bluefors team, and clients get to focus on what matters to them: results.

One of the Lab’s current customers, QuantrolOx, recently used the Lab to test the integration of their Quantum EDGE software with the suite of included measurement electronics, and additional devices they added themselves. Vishal Chatrath, QuantrolOx’s co-founder, is keen to promote the benefits of the service:

“Being able to test on a dedicated system and integrate leading control electronics from providers such as Qblox, Quantum Machines and Zurich Instruments, has been hugely beneficial. With the new XLD system, QuantrolOx has the ability to test its software with multiple electronics and multiple types of QPUs at the same time. It also gives us the ability to work with larger QPUs, allowing us to test new techniques and further improve the performance of our software.”

Access to a dedicated testing environment in which an actual quantum computer can be operated is a fundamental requirement for many startups. Bluefors Lab provides companies a convenient, affordable, low-risk path to the tools, measurement infrastructure and expertise needed to carry out R&D on benchmark systems. At the same time, collaborating with an industry leader like Bluefors gives startups an opportunity to increase visibility and build deeper networks in the quantum ecosystem. www.bluefors.com

Image: Bluefors Lab in Delft, Netherlands, offers cryogenic measurements as a service, providing startups and smaller institutions with cost-effective access to advanced cryogenic cooling systems and a full suite of measurement electronics necessary for quantum research, along with comprehensive support from experienced staff. Credit: Bluefors