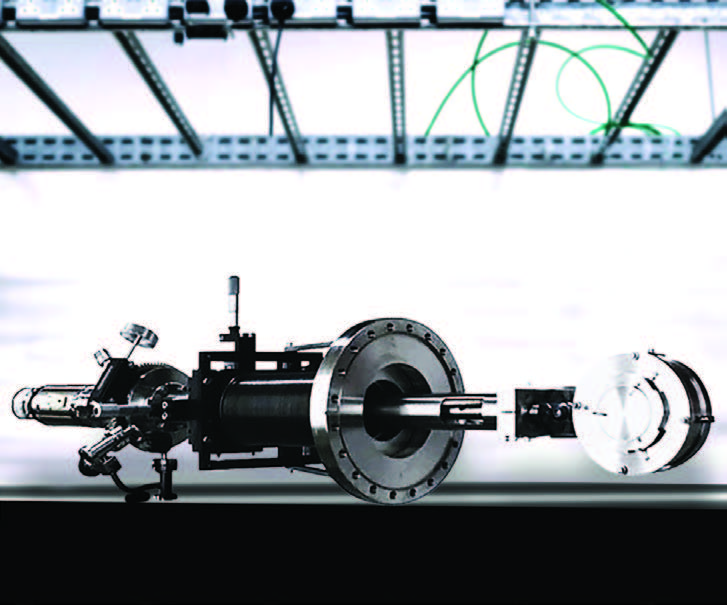

Thermionics Laboratory Empowers Precision Nanofabrication, Ultrahigh Vacuum Manipulator for Glancing Low Angle Deposition

What does a leading optics manufacturer do when striving to develop cutting-edge lenses for high-resolution imaging systems? Their quest for flawless optical performance hinges on achieving nanostructured surfaces that minimize light scattering and maximize transmission efficiency.

What does a leading optics manufacturer do when striving to develop cutting-edge lenses for high-resolution imaging systems? Their quest for flawless optical performance hinges on achieving nanostructured surfaces that minimize light scattering and maximize transmission efficiency.

In the intricate world of advanced materials and nanotechnology, achieving precise fabrication techniques is often the greatest challenge. Traditional methods struggle to meet these meticulous demands. This is where Thermionics Laboratory, Inc. steps in with their Ultrahigh Vacuum (UHV) Manipulator tailored for Glancing Low Angle Deposition (GLAD), revolutionizing how industries tackle the complexities of nanoscale fabrication.

Overcoming Precision Challenges in Nanotechnology

The optics industry is one of many industries with a pressing need for uniform and finely tuned optical coatings. Conventional deposition methods can result in inconsistent performance and wasted resources. The GLAD Manipulator by Thermionics directly addresses these challenges with several key features:

Precise Deposition Control: Featuring ±180° polar rotation and continuous azimuthal rotation capabilities, the manipulator ensures uniform coating thickness and deposition angles crucial for optimizing optical clarity and performance.

Temperature Management: Advanced heating options and liquid nitrogen cooling maintain substrate integrity during deposition, enabling precise material properties tailored to demanding optical applications. This careful control of temperature is vital for creating the high-quality coatings required for advanced optics.

By integrating Thermionics GLAD Manipulator into their production process, researchers have achieved notable advancements:

Enhanced Precision: The manipulator’s XYZ movements facilitated exact substrate positioning, allowing for tailored nanostructure arrangements that significantly improved optical performance. This level of precision is essential for developing optics that meet the highest standards of resolution and clarity.

Efficiency Gains: Automated control features streamline production workflows, reduce lead time and enhance overall yield while maintaining superior quality standards. The result is not only better performance but also more cost-effective manufacturing processes.

Future Prospects

As Thermionics Laboratory continues to innovate, their commitment to advancing nanotechnology remains unwavering. Their range of products, from thin-film deposition equipment to advanced manipulators, supports diverse applications in research and industry, from academic institutions to Fortune 500 companies. The Thermionics GLAD Manipulator exemplifies the pinnacle of precision engineering, empowering industries to push boundaries and unlock new possibilities in nanofabrication. www.thermionics.com

Image: GLAD Manipulator. Credit: Thermionics Laboratory