Success in Harsh Environments: Signaling the Future of Cryogenic Communications

XMA, with its space heritage spanning from low-Earth orbit (LEO) to deep space exploration units, embarked on a journey to enter the supply chain for quantum computing more than 10 years ago. The driving force behind this industry expansion was XMA’s success in cryogenic temperatures down to approximately 4 K in space environments. XMA managed to strike the perfect balance between rugged materials that remained non-superconductive at cold temperatures and low-mass products. When quantum technologists cooled these components to millikelvin temperatures, the specifications remained unchanged. This consistent performance from ambient to cryogenic conditions has become XMA’s baseline for success. With the cross-pollination of knowledge between the space and quantum industries, XMA has experienced steady growth in both sectors, thanks to its novel designs and successful environmental testing. As space exploration and quantum computing continue to advance, XMA leverages the newfound knowledge from each industry to improve the other.

XMA, with its space heritage spanning from low-Earth orbit (LEO) to deep space exploration units, embarked on a journey to enter the supply chain for quantum computing more than 10 years ago. The driving force behind this industry expansion was XMA’s success in cryogenic temperatures down to approximately 4 K in space environments. XMA managed to strike the perfect balance between rugged materials that remained non-superconductive at cold temperatures and low-mass products. When quantum technologists cooled these components to millikelvin temperatures, the specifications remained unchanged. This consistent performance from ambient to cryogenic conditions has become XMA’s baseline for success. With the cross-pollination of knowledge between the space and quantum industries, XMA has experienced steady growth in both sectors, thanks to its novel designs and successful environmental testing. As space exploration and quantum computing continue to advance, XMA leverages the newfound knowledge from each industry to improve the other.

The needs of the space and quantum computing industries bear striking similarities. Space requires low-mass, mechanically rugged and cryogenic components. On the other hand, quantum computing emphasizes reducing the mechanical footprint rather than mass. Additionally, quantum computing components must not only function flawlessly in cryogenic environments but also contribute to maintaining these environments by effectively thermalizing and redirecting the heat generated by the signals. In both industries, addressing these challenges revolves around one overarching necessity: clean radio frequency (RF).

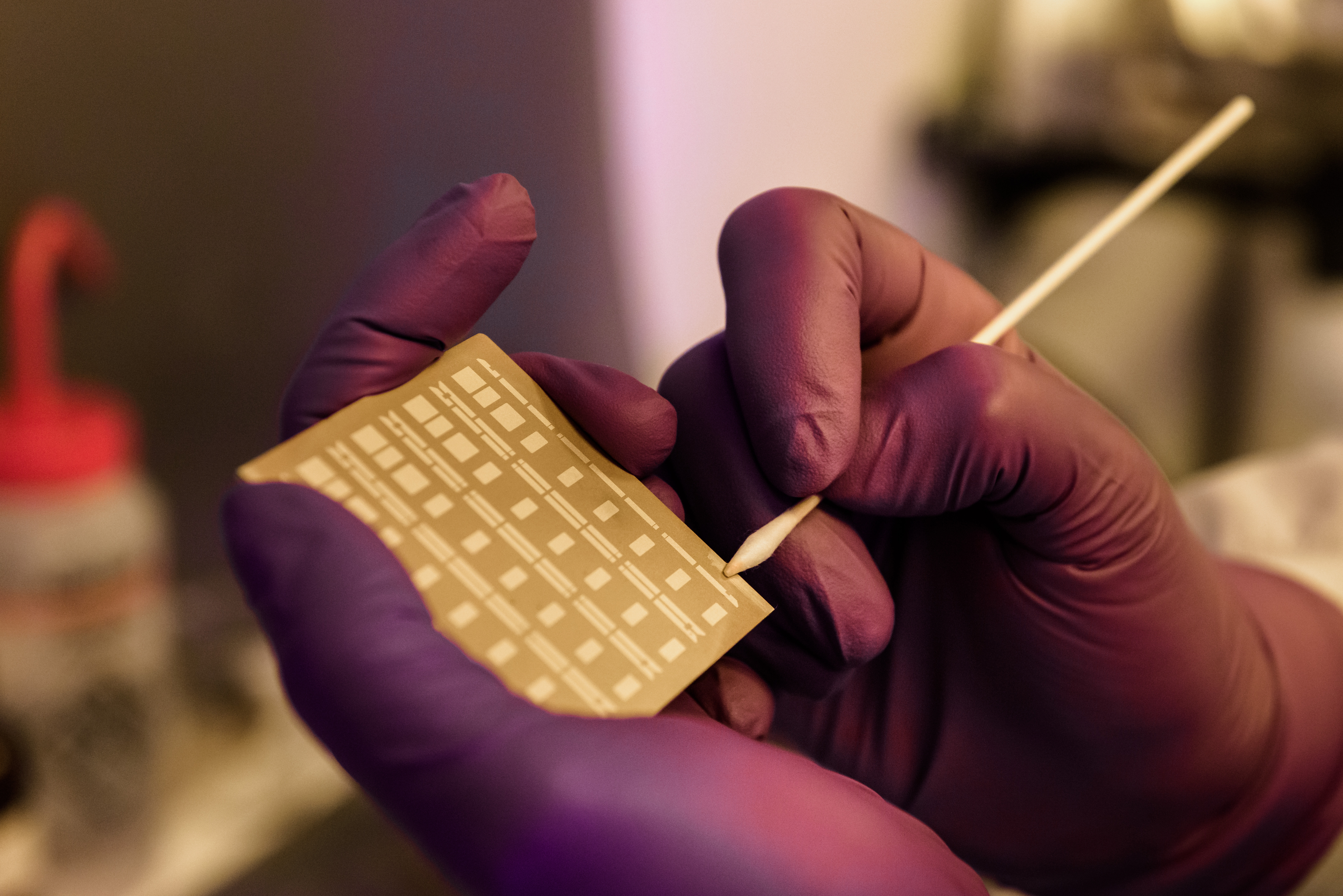

XMA finds itself in a unique position to deliver disruptive, cutting-edge products to these industries. The company’s journey begins with its thin film lab where vertical integration and adherence to the AS9100 risk reduction standards ensure a smooth yet highly regulated transition from design engineering to full-rate production. XMA’s engineers enjoy complete access to an in-house thin film resistor lab, driving the development of new products and process updates. This includes terminations with smaller chips and attenuators with new chip substrates. Direct access to the lab, combined with close industry partnerships, serves as the driving force behind XMA’s innovation.

Over the past two years, XMA has introduced myriad new products tailored to the space and quantum industries. These innovations encompass components in traditional coaxial packages, as well as those that deviate from the traditional product line, aiming for the future of embedded attenuation, new interconnect types and flex cabling. Although each new component is designed to fulfill a multitude of objectives, they never compromise on delivering high quality RF signals. This commitment to excellence in RF remains at the forefront of XMA’s designs.

Over the past two years, XMA has introduced myriad new products tailored to the space and quantum industries. These innovations encompass components in traditional coaxial packages, as well as those that deviate from the traditional product line, aiming for the future of embedded attenuation, new interconnect types and flex cabling. Although each new component is designed to fulfill a multitude of objectives, they never compromise on delivering high quality RF signals. This commitment to excellence in RF remains at the forefront of XMA’s designs.

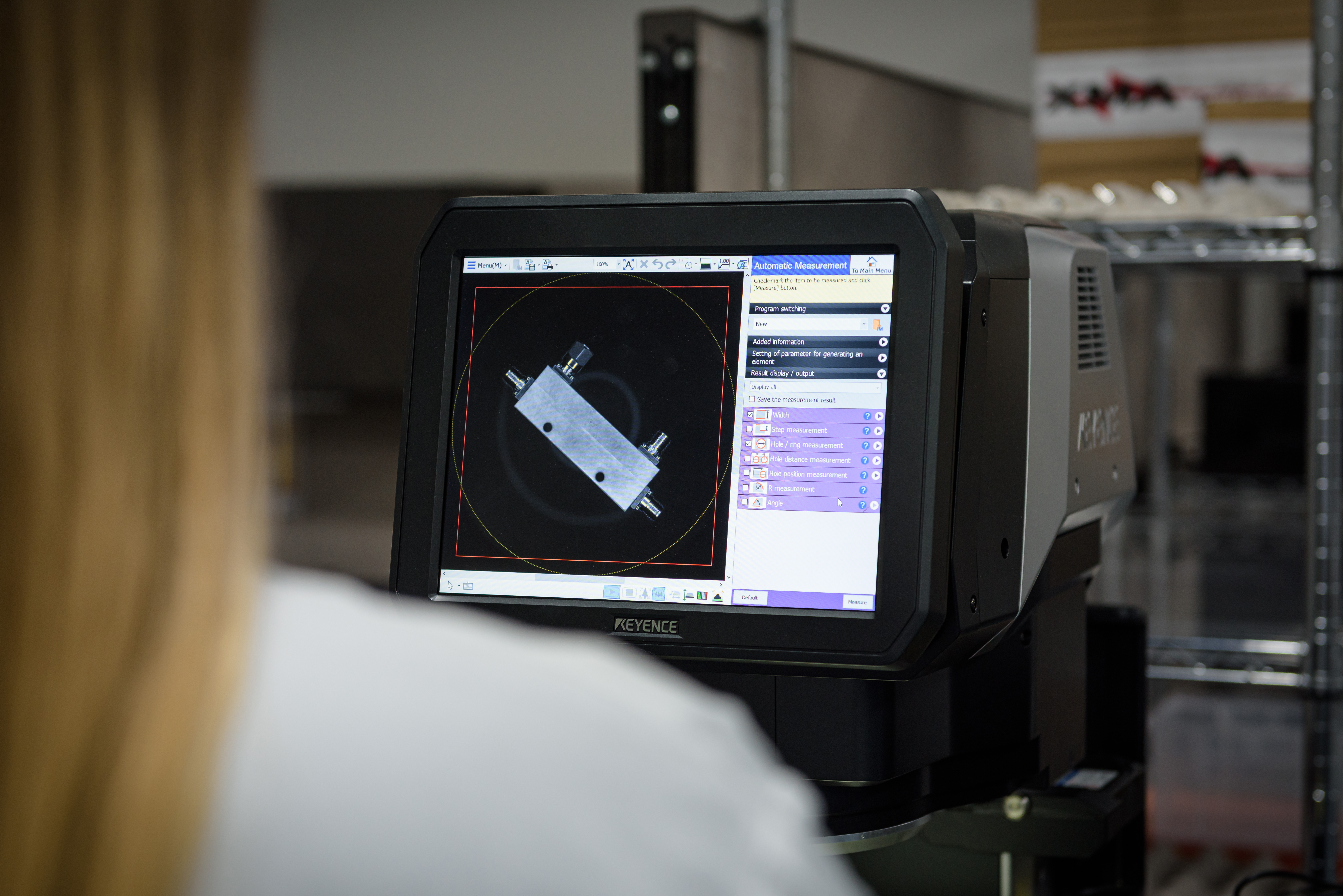

XMA’s latest coaxial components boast redesigned mechanical interfacing, modern connectors, refreshed materials that enhance thermalization and advanced capabilities to prevent interruptions caused by high energy signals. For instance, XMA’s new cryogenic directional coupler leverages updated mechanical interfacing and materials to fit within a smaller package size. Couplers designed for space applications utilize a lighter-weight aluminum housing, while those intended for quantum computing employ a well-thermalized gold-plated copper housing. Although these designs share numerous features that produce reliable and clean RF, XMA’s deep industry knowledge enables seemingly minute changes that ultimately lead to superior system performance.

In parallel to its dedication to coaxial products, XMA is boldly venturing into the development of non-coaxial components, marking a significant shift in the company’s innovative approach. For example, XMA is developing a revolutionary flexible cable focused on low crosstalk, high signal line density and minimal heat load. Although the current market demand for these cables comes from the quantum community, the space community is following close behind. XMA is eager to implement the nuanced requirements from the space community and continue to develop high performance cryogenic cables with clean RF. Leveraging space heritage, thin film innovation and industry collaborations, XMA is signaling the future of cryogenic communication. www.xmacorp.com

Image 1: Thin film technician processing a resistor board. Credit: XMA Corporation

Image 2: XMA directional coupler under test. Credit: XMA Corporation